How material shortages could effect you

Why cant the UK get materials?

"build back better" has been a message put out by the Government during the current Covid 19 Pandemic and the UK has taken this very literally as we have seen a massive increase in demand for construction over the past year

Construction output has been forecasted to raise 12.9% in 2021 and 5.2% in 2022 which puts more pressure on the supplying of materials needed to complete these jobs

The massive increase of supply has come at a bad time for the UK given the current pandemic compared with the effects of Brexit

Shipping costs from Asia have increased 500% between June 2020 and June 2021 making the cost. Overall shipping costs remained around 10% higher in the same time period

so why cant the UK get materials?

There have been global supply issues as it seems that construction demand has risen all over the world. The countries that provide the materials we need are now more reluctant to sell them as they are using them for their own construction projects.

Raw materials like Steel and Timber are expected to stay inflated for the foreseeable future unlike materials like Cement which should be able to respond to the high demand as its produced mainly in the UK

The UK's departure from the EU has been cited as one of the main shortages in labour and materials. am already existing shortage of materials could be made worse on January 1st when the UK will stop recognising the European CE Certification of products

Products will need a UKCA marking, this can be obtained through getting a product tested in a UK Facility, a process which can cost as much as £50,000

What effects do material shortages cause the UK

The UK has been experiencing a materials shortage which could collide with the labour shortages we are expecting as we get closer to the summer holidays.

the low supply has stemmed from global demand mixed with external factors like Covid leading to the closure of factories outside of the UK

As the demand is picking up, key materials like steel are remaining in short supply and will continue to raise if the demand continues. Constriction firms have been advised to better ration their resources and save the materials for bigger jobs with larger impact if the right materials are not supplied

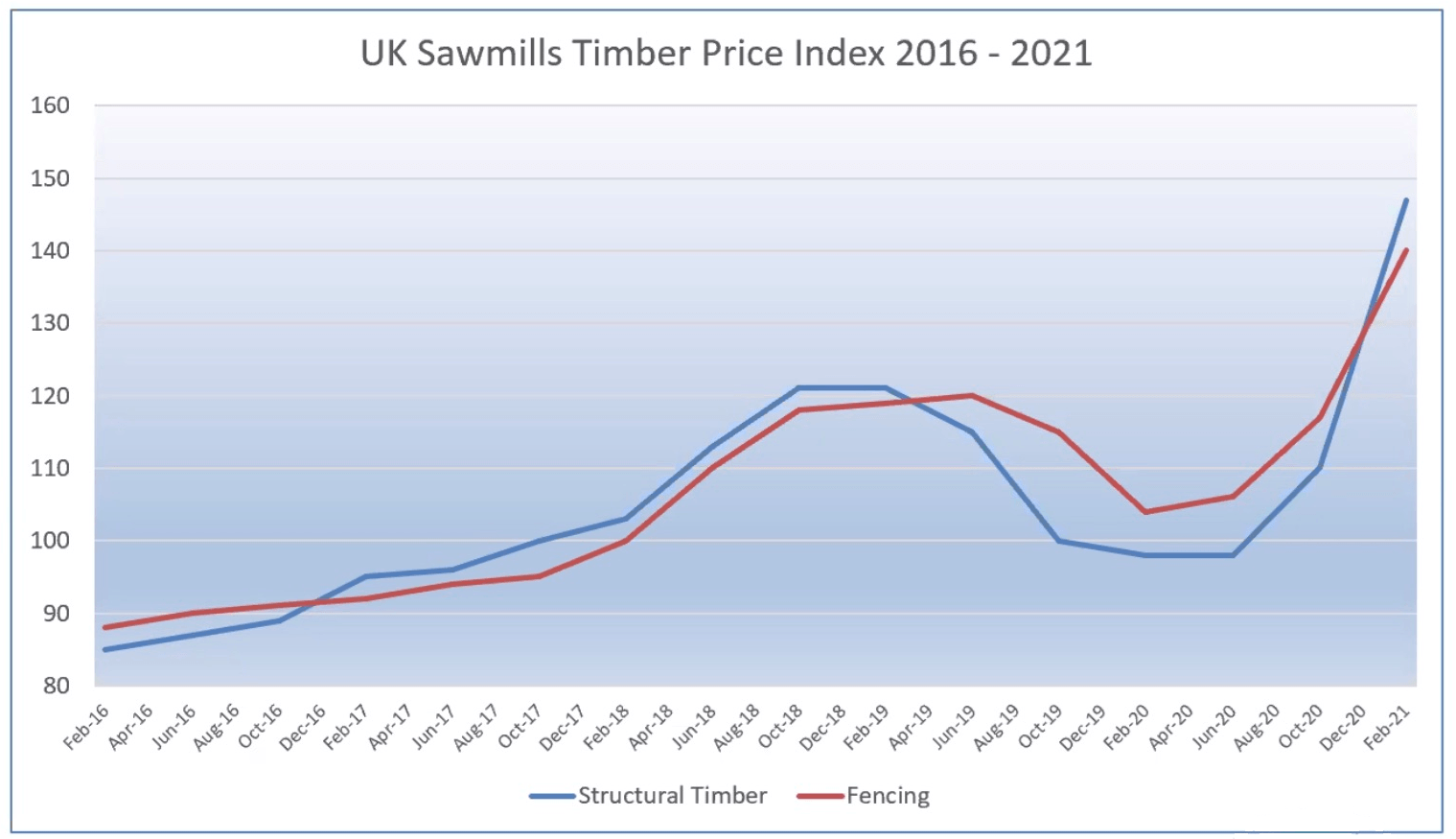

As you can see from this graph the materials have shot up in value and don't look like they are stopping yet

Raw materials may be hard to find for the next few month and some will be able to come back into supply sooner than others.

How can the material shortage be solved?

Unfortunately one of the ways to increase the raw material shortage is by increasing prices. This makes buying the raw materials only useful for the people who need them and will lower overall demand allowing the market to build up again.

Another unfortunate way to solve the problem is to just wait for more materials to be made. Depending on what you need this could take a few months or over a year before you see materials going back to the old prices but eventually demand will fall and result in a lower price in the future

Some companies are campaigning for the government to support the industry or many fear it could result in the closure of many businesses

Many analysts are hopeful that materials will return to their previous prices (most within a few months). Everyone will have to work together in the construction industry to assure we all survive it through this rough period